In the food processing industry, quick freezing technology is a key link in ensuring food quality and extending shelf life. With consumers' increasing demands for food safety, nutritional retention, and product standardization, food factories are becoming increasingly strict in their selection of quick freezing equipment. In recent years, the double spiral quick freezing machine has gradually become the preferred equipment for food factories due to its technological advantages.

Efficient and uniform: breaking through the bottleneck of traditional quick freezing technology

Traditional quick freezing equipment, such as flat or upright quick freezing machines, suffer from low efficiency and uneven temperature control. If the freezing speed of food is too slow during the quick freezing process, the water in the intercellular space will form large ice crystals, which will damage the tissue structure of the food and lead to a deterioration in taste after thawing. In addition, the traditional equipment has a single cold air circulation path, which can easily cause uneven freezing inside and outside the food, and even some areas may not be completely frozen, increasing the risk of spoilage.

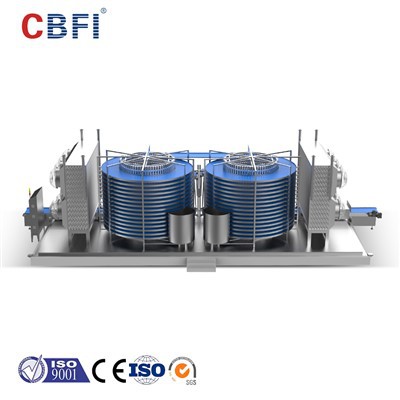

The double spiral freezer uses a unique double spiral propulsion structure to slowly lift food in an "S" - shaped trajectory inside a closed box, allowing each product to evenly come into contact with low-temperature cold air. Its core advantages are reflected in the following two points:

1. Efficient freezing ability: Through forced convection technology, cold air can penetrate the surface of food, accelerate heat exchange, and shorten freezing time by 40% -60%. For example, traditional equipment may take 2-3 hours to freeze dumplings, while double spiral equipment can complete it within 1 hour.

2. Temperature field uniformity: The double spiral design of the spiral propulsion path and multi-point cold air distribution system ensures that the temperature difference between different parts of the food during freezing does not exceed 1 ℃, greatly reducing the damage of ice crystals to the cell structure and preserving the original flavor and nutrition of the food.

Flexible adaptation: meeting the needs of diversified production lines

There are a variety of products in the food processing industry. From quick-frozen dumplings and rice dumpling to fish balls and meat products, the compatibility of quick-frozen equipment is highly required. The double spiral quick freezing machine has achieved "one machine for multiple uses" through the following design:

1. Modular design: The width and chain spacing of the spiral conveyor belt can be adjusted according to the product size, and even switched to a drum or grid conveyor belt, suitable for granular, block or sheet food.

2. Flexible parameter adjustment: Through the PLC intelligent control system, the freezing temperature (-30 ℃ to -40 ℃), wind speed (0-6m/s), and dwell time (10-60 minutes) can be switched with one click, quickly matching the process requirements of different products.

3. Low loss operation: For fragile or high moisture foods (such as fish paste products), the equipment can reduce propulsion speed and wind pressure, minimize physical damage, and control the loss rate below 1%.

Safety and Health: Building a Food Safety Defense Line

Food safety is the bottom line of food processing, and a sealed environment is the key to ensuring hygiene. The double spiral quick freezing machine achieves the following safety protection through a fully enclosed design:

1. Preventing cross contamination: The equipment adopts a sealed box and is equipped with a positive pressure circulation system to prevent external dust and microorganisms from entering; At the same time, the food is completely frozen in a closed space, with no risk of contact contamination.

2. Compliance certification: Complies with international food safety standards such as GMP and HACCP, with key components made of 304 stainless steel material that is easy to clean and corrosion-resistant, meeting FDA and EU health certification requirements.

3. Energy saving and consumption reduction: Through intelligent temperature control and waste heat recovery technology, it can save 20% -30% energy compared to traditional equipment, reduce carbon emissions, and conform to the trend of green production.

Space optimization: breaking the limitation of factory area

For food enterprises, especially small and medium-sized enterprises, the factory area is often a bottleneck that restricts the expansion of production capacity. The double spiral quick freezing machine adopts a three-dimensional spiral structure, which increases the space utilization rate by more than 50% compared to traditional equipment:

1. Compact design: The highly integrated equipment has a volume that is only one-third of traditional linear equipment, and can be flexibly installed in corners or narrow spaces of factories.

2. Low footprint: Taking equipment with a daily processing capacity of 1 ton as an example, traditional equipment requires 60 square meters, while double spiral equipment only requires 25 square meters, saving enterprises about 60% of factory costs.

3. Compatible with automation: It can seamlessly integrate with robot palletizing and visual inspection systems, forming a full process automation chain from production to packaging, reducing the need for manual operation space.

The popularization of double spiral quick freezing machines is essentially the result of the combined effect of technological innovation and market demand. It not only solves the efficiency bottleneck of traditional quick freezing technology, but also redefines the "standardization" and "refinement" of food processing through safety, flexibility, and space optimization. For food factories, choosing double helix equipment is not only an equipment upgrade, but also a long-term investment in quality commitment and sustainable development.

Hot Tags: double spiral quick freezing machine is the preferred choice for food factories, China, manufacturer, factory, price, buy