Cooling requirements and importance after baking bread

After baking, bread needs to be immediately cooled to ensure its taste, texture, and shelf life are not affected. Traditional methods typically use natural cooling or air cooling techniques, but these methods are time-consuming and can increase the risk of water loss and microbial contamination. In order to overcome these problems, the modern food industry generally adopts mechanical freezing technology, among which the double spiral quick freezing machine has become one of the preferred equipment due to its high efficiency and reliability.

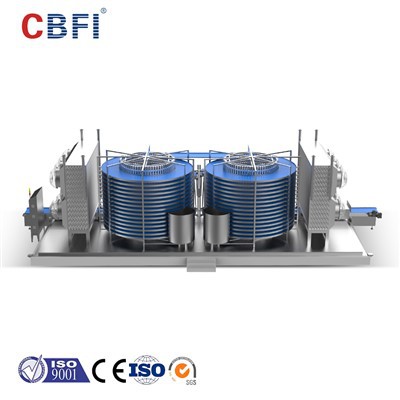

Working principle of double spiral quick freezing machine

Double spiral quick freezing machine is a mechanical equipment designed based on the principle of convective heat transfer. It consists of two parallel spiral conveyor belts that rotate in opposite directions to evenly distribute the products to be frozen in the internal space of the machine. After the bread enters the freezer, it will be placed in a low-temperature environment where the air circulates at high speed, quickly taking away the surface heat of the bread and causing its temperature to quickly drop to the set value.

Key steps in the freezing process

1. Pre cooling stage: When bread first enters the freezer, it undergoes a preliminary cooling process. During this period, the main objective is to lower the center temperature of the bread and bring it closer to the freezing point. This stage usually lasts for a few minutes, depending on the size of the bread and the initial temperature.

2. Core freezing stage: As the temperature of the bread further decreases, tiny ice crystals begin to form. This stage is the most critical part of the entire freezing process, as if the freezing speed is too slow, it can lead to the formation of large ice crystals and damage the bread tissue structure. Therefore, it is necessary to strictly control the temperature and time parameters of this stage, usually recommended to maintain around -35 ° C, and try to shorten the time required for this stage as much as possible.

3. Stable stage: When the bread is completely frozen, it enters the final stage - the stable stage. The main task at this point is to make the overall temperature of the bread consistent and eliminate any possible thermal gradients. In general, the temperature during the stable phase should be maintained below -18 ° C to ensure that the bread remains in optimal condition throughout the entire storage and transportation process.

Temperature requirements and parameter settings

The freezing temperature requirements may vary for different types of bread. However, generally speaking, the following points can serve as reference standards:

The initial feed temperature should not be too high, usually not exceeding 40 ° C;

The temperature during the core freezing phase should be controlled between -35 ° C and -40 ° C;

The final outlet temperature during the stable phase needs to reach -18 ° C or lower.

In addition, attention should be paid to adjusting auxiliary parameters such as air flow rate and humidity level to achieve the most ideal freezing effect. For example, increasing the air flow rate appropriately can help accelerate the heat transfer rate, but at the same time, it may also cause the bread surface to dry or even crack; Reasonable control of relative humidity can effectively reduce the probability of such problems occurring.

Optimization measures to improve bread quality

Although the double helix quick freezing function significantly improves the efficiency and quality of bread freezing, additional measures still need to be taken in practical applications to maximize its benefits. For example:

1. Choose the appropriate feeding method to ensure that each piece of bread has sufficient exposure to cold air;

2. Regularly clean and maintain equipment to prevent residue accumulation from affecting performance;

3. Combined with packaging technology, provide appropriate protective layer for bread before freezing to avoid unnecessary damage caused by direct exposure to air.